Rolling machine is an important metal processing equipment widely used in industries such as steel and metallurgy.

Its main function is to process metal plates into the desired coil shape through processes such as curling and rolling.

The working accuracy of the rolling machine has a significant impact on production efficiency and product quality.

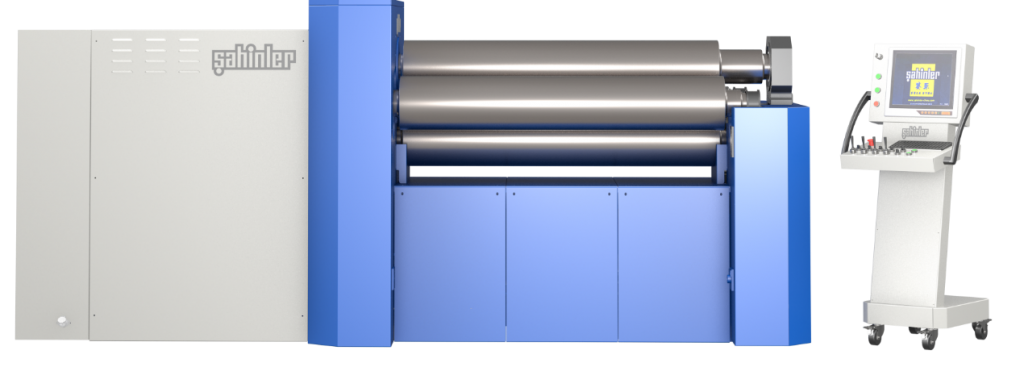

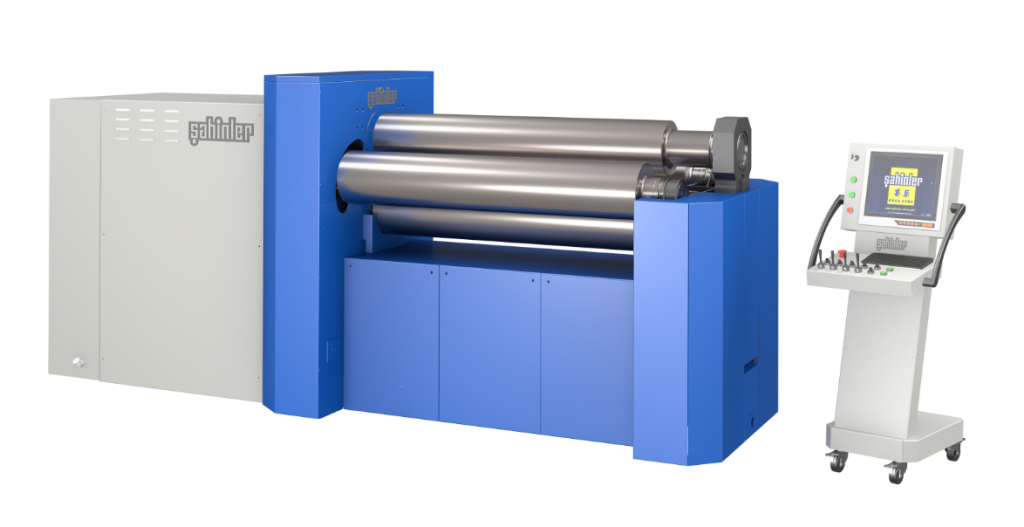

The working accuracy of a plate rolling machine depends on multiple factors, among which the most important are the machine tool structure and control system.

The machine tool structure includes the frame, rollers, transmission system, etc. If the machine tool structure is stable and rigid, it can effectively reduce machining errors.

The control system can monitor and adjust the parameters during the machining process to ensure the stability of machining accuracy.

- For the plate rolling machine, the working accuracy is mainly reflected in the following aspects:

(1) Thickness accuracy: The plate rolling machine can process metal plates according to the predetermined thickness, and its thickness accuracy refers to the degree of difference between the processed plate thickness and the predetermined thickness.

High precision rolling machines can control thickness errors within a very small range.

(2) Width accuracy: The rolling machine can also adjust the width of the metal sheet to meet the design requirements.

Width accuracy refers to the deviation between the width of the processed sheet and the predetermined width, and high-precision rolling machines can achieve smaller width errors.

(3) Bending accuracy: The bending machine can also change the shape of the metal sheet by adjusting the pressure between the rollers, achieving bending processing.

Bending accuracy refers to the deviation between the shape of the processed sheet metal and the design requirements, and high-precision bending machines can achieve precise bending.

- To improve the working accuracy of the plate rolling machine, attention should be paid to the following points:

(1) Choose high-quality machine structure and control system to ensure its stability and accuracy.

(2) Using high-quality rollers and transmission devices to reduce mechanical vibration and fit clearance, and improve machining accuracy.

(3) Strengthen maintenance and regularly inspect all components of the machine tool to ensure its normal operation and stable accuracy.

(4) Optimize processing technology and control parameters, reasonably set parameters such as speed and pressure during the processing, and reduce errors.

The working accuracy of the rolling machine has a significant impact on product quality and production efficiency:

(1) High working accuracy can ensure the dimensional and shape accuracy of the final product, and improve product quality.

(2) Stable work accuracy can reduce the accumulation of errors in the production process and improve production efficiency.

(3) High work accuracy can reduce secondary processing and repair of products, and lower production costs.

In summary, the working accuracy of the plate rolling machine is crucial for the metal processing industry.

By selecting high-quality machine tool structures and control systems, and strengthening maintenance and optimizing process parameters, the working accuracy of the plate rolling machine can be effectively improved, and product quality and production efficiency can be enhanced.