Plate rolling machine is a mechanical device used to roll metal sheets into cylindrical, flat, or other shapes.

It plays a very important role in industrial production and is widely used in the manufacturing industry, especially in the fields of steel, automobiles, ships, and construction.

This article will delve into the working principle and technical characteristics of the rolling machine.

1、 The working principle of a rolling machine can be simply described as the plastic deformation of a metal sheet through rolling, thereby achieving the goal of bending it into the desired shape.

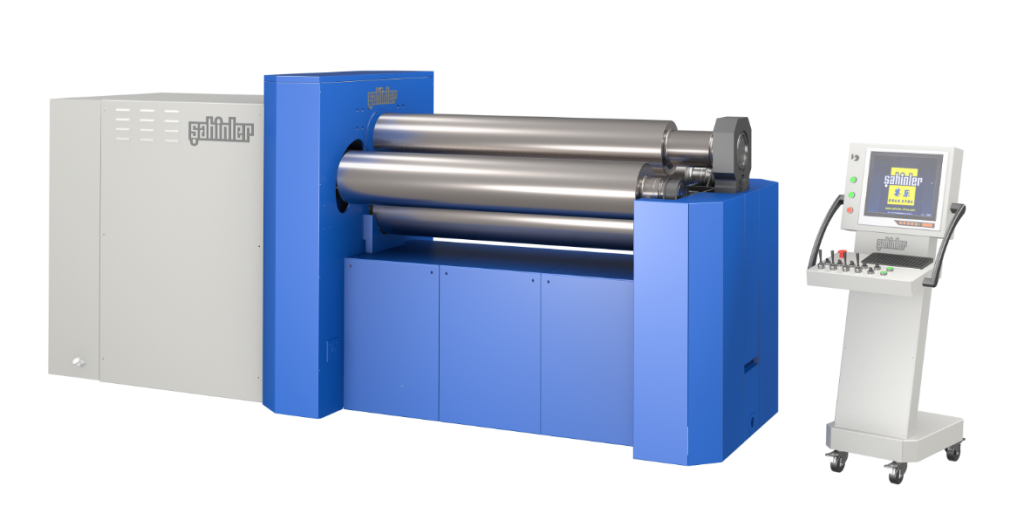

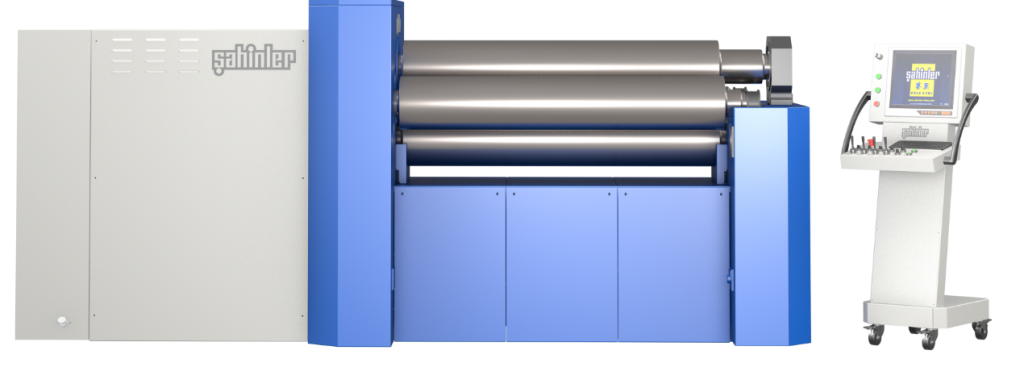

The rolling machine mainly includes components such as frame, motor, reducer, roller shaft, lubrication system, etc.

Place the metal sheet to be processed on the rolling machine.

Then, the motor and reducer drive the roller shaft to rotate, causing the metal sheet to move relative to the roller shaft.

Next, the rollers on the roller shaft apply pressure to the metal sheet, causing it to undergo plastic deformation in order to bend into the desired shape. By adjusting the position and angle of the rollers, the bending degree and shape of the metal sheet can be controlled.

2、 Technical characteristics

- Multi roll structure: The plate rolling machine usually adopts a multi roll structure, and the spacing between the rollers can be adjusted to meet different processing requirements for the metal sheet.

The materials of rollers are also diverse, commonly including hard alloy and tool steel, to ensure the wear resistance and service life of the rollers.

- Automation control: Modern plate rolling machines generally adopt automation control systems, which can achieve precise control of the processing process.

By setting appropriate processing parameters such as roller position, pressure, speed, etc., the stability and consistency of processing quality can be ensured.

- Multifunctionality: The rolling machine has strong adaptability and can process metal sheets of different types and thicknesses.

Some advanced bending machines can also achieve various processing methods, such as pre bending, composite bending, etc., further expanding their application scope.

- Efficient and energy-saving: With the advancement of technology, the rolling machine has also made significant improvements in energy conservation and environmental protection. By adopting advanced motors, hydraulic systems, and control technology, energy consumption can be reduced and production efficiency can be improved, reducing the impact on the environment.

- Safety and reliability: The design of the rolling machine takes into account the safety of the operators and the reliability of the equipment.

For example, protective covers and safety doors have been installed to reduce the risk of accidents for operators;

For example, protective covers and safety doors have been installed to reduce the risk of accidents for operators;

Strict quality control and testing have been carried out on key components, improving the stability and reliability of the equipment. As an important metal processing equipment, the rolling machine has technical characteristics such as multi roll structure, automatic control, multifunctionality, high efficiency, energy conservation, and safety and reliability.

With the needs of industrial development, plate rolling machines are constantly innovating and improving to meet the processing needs of different industries. I believe that with the development of technology, the rolling machine will develop more advanced technologies and applications in the future, making greater contributions to the progress of the manufacturing industry.