Plate bending machine is an important equipment for metal processing, which shapes the future metal processing technology with its high efficiency, accuracy and flexibility.

In this paper, the working principle, application field and future development of plate bending machine will be deeply analyzed, and related topics will be derived to enrich the content of the article.

First of all, let’s explain the working principle of the plate bending machine.

Plate bending machine is processed by coiling and distributing metal materials.

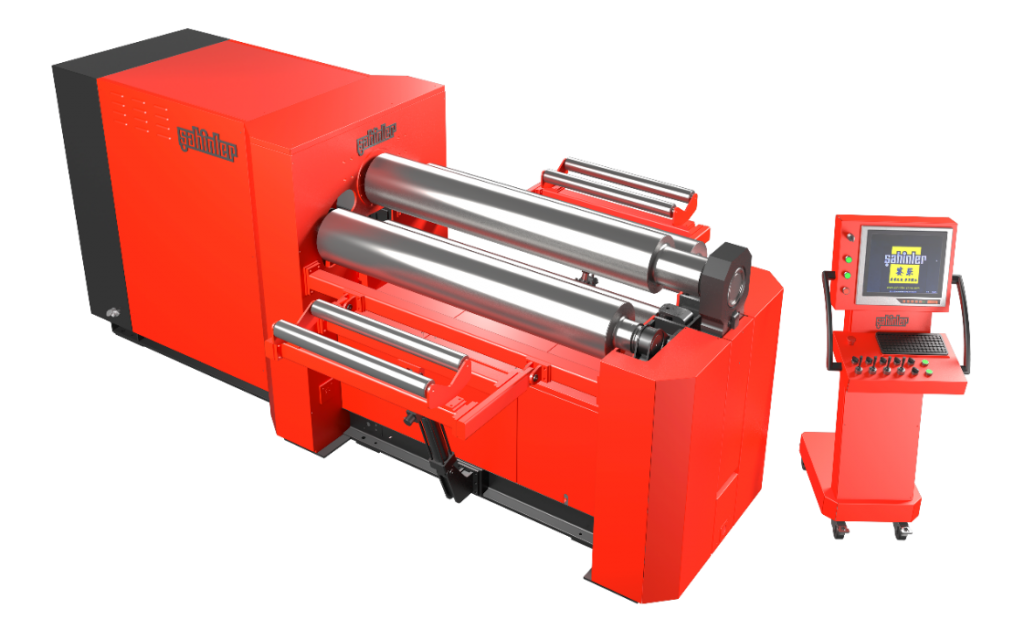

It usually consists of two main parts, namely the coiling system and the molding system.

The coiling system is used to unwind the metal material from the reel and deliver it to the molding system.

The forming system uses rollers or rollers to press, bend or fold metal materials to achieve the required shape and size.

Plate bending machine is widely used in various fields.

First of all, it plays an important role in the construction industry.

Plate bending machine can process and manufacture all kinds of building materials, such as roof tiles, steel structures and wallboard, and provide reliable support for building projects.

Secondly, plate bending machine is also an essential equipment in automobile manufacturing.

It can process metal materials into automobile body, door, hood and other parts to ensure the quality and safety of automobiles.

In addition, plate bending machines are widely used in electronics, metallurgy, energy and other industries to meet the processing needs of various metal materials.

With the development of science and technology, the plate bending machine is constantly innovating and evolving.

In the future, with the promotion of industrial automation, the plate bending machine will be more intelligent and automatic.

- In terms of intelligence, the plate bending machine will realize real-time monitoring and optimization adjustment of process parameters with the help of advanced sensing technology and data analysis ability, and improve production efficiency and product quality.

- In terms of automation, the plate bending machine will realize a higher degree of automatic operation, reduce manual intervention, reduce labor intensity and human error, and improve production efficiency and safety.

- At the same time, the plate bending machine will be more environmentally friendly and energy-saving.

By optimizing design and application of new materials, waste generation and energy consumption can be reduced and sustainable development can be realized.

As a kind of metalworking equipment, plate bending machine plays an important role in shaping the future metalworking technology.

Its working principle, application field and future development prospect deserve our in-depth study.

Through continuous innovation and evolution, plate bending machine will provide more efficient, accurate and environmentally friendly metal processing solutions for various industries.