Doors and windows are one of the important peripheral protective structures of buildings, serving functions such as wind and rain protection, insulation, sound insulation, lighting, and ventilation. With the improvement of people’s living standards, the requirements for doors and windows in decoration are becoming higher and higher. As a widely used product, doors and windows have broad market prospects due to their unique advantages. Under the premise of leveraging its own advantages and improving the problems encountered during use, new high-performance doors and windows have begun to enter the sight of consumers.

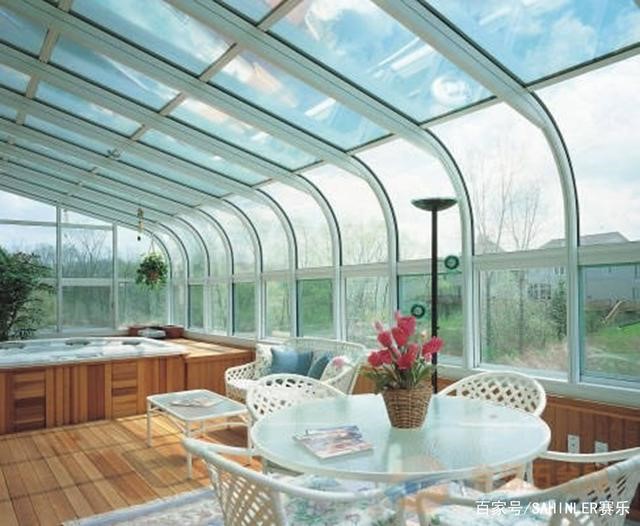

The most commonly used aluminum profile in current door and window processing is the broken bridge aluminum alloy profile, which has the advantages of light weight, high strength, good water and air tightness, good fire resistance, large lighting surface, atmospheric corrosion resistance, long service life, good decoration effect, and good environmental performance. Due to its complex cross-sectional shape, wrinkles are easily generated during bending processing, which affects the aesthetics of doors and windows.

Sahinler has successfully developed a variable curvature CNC profile bending machine with unique core algorithms and rich bending processing parameters. After importing CAD drawings, the machining trajectory is automatically generated, and the pressure is automatically adjusted, completely solving quality problems such as wrinkling, scratches, distortion, indentation, and smoothness that are prone to occur during aluminum profile bending processing, meeting customers’ requirements for high-quality products.

Performance characteristics of high-precision CNC EVO system

Speed self matching: The speed of the three directly connected drive axles is automatically matched, effectively avoiding slipping and pulling on the surface of the workpiece during the curling process.

Single arc multiple forming: When we need multiple bending forming, we can automatically generate CNC programs to achieve the required shape of the workpiece for bending and rolling.

Multi radius arc repetitive machining: Multi radius and multi curvature arcs can also be repeatedly curled to improve the accuracy of the curled arc.

Variable arc production: Flexible production of workpieces that meet the requirements of single arc and multi radius, multi curvature, and multi segment arcs.

Servo hydraulic system: The hydraulic system has high stability, low hydraulic oil temperature, energy-saving, and emission reduction.