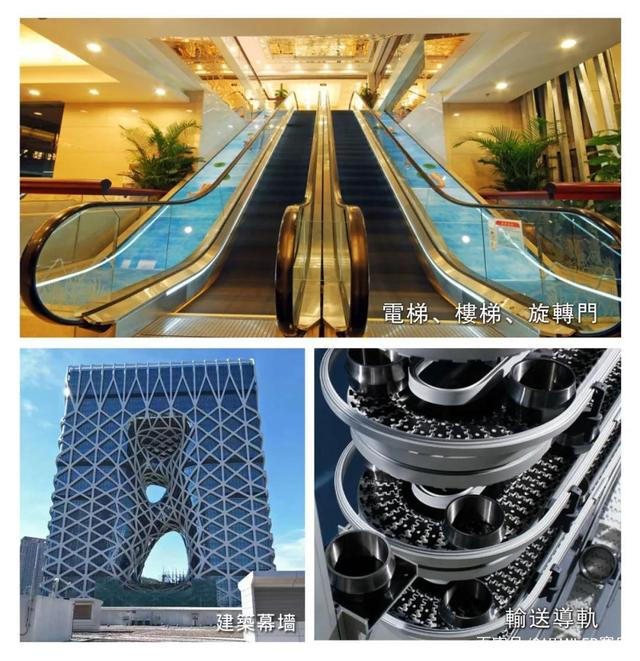

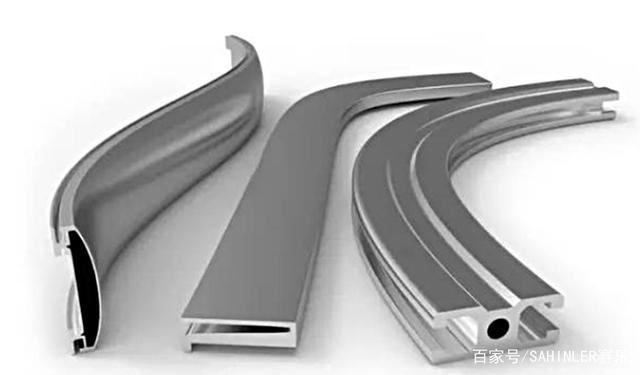

The profile bending machine can complete the pre-bending, bending, and correction processes in one circle; This machine has advanced structure and full functionality, and can be placed vertically or horizontally according to usage. The biggest advantage is the high accuracy and work efficiency of bending profiles, making it a more advanced profile forming equipment in the 21st century. This equipment is widely used in the production of various circular flanges in automotive, elevator, petroleum, chemical, steel structure, mechanical manufacturing, and other industries.

The entire profile bending machine has sufficient strength and rigidity to meet the bending of profiles within the machine’s capacity range. Changing the mold can bend profiles such as angle steel, flat steel, square steel, U-beam, I-beam, round steel, steel pipes, etc. This model has advanced structure, reliable operation, small size, and complete functions, making it an advanced profile forming equipment at home and abroad. Widely used in industries such as boilers, shipbuilding, hydropower, and metal structures.

Starting from the entry of profile bending machines into the domestic market, today we can divide the development process of profile bending machines in China into two stages, namely the simple profile bending machine stage and the high-precision profile bending machine stage. The smart level of the profile bending machine industry means its breadth and depth of application. Currently, the profile bending machine is only in a relatively low level of primary smartness stage. The continuous development of the domestic profile bending machine industry has put forward high requirements for smartness, which means it is necessary and capable for us to vigorously develop advanced smart profile bending machine technology based on specific application needs.